- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

300000

T/T, Western Union, Paypal

Shanghai, China

It can be used for current monitoring and protection in small current grounding systems, fire leakage systems, three-phase current unbalance detection and other equipment.

Main Feature

Enclosed by epoxy resin, good seismic performance

Perforation method, the hole diameter is from φ12mm-φ260mm, which is convenient for busbar installation

High magnetic permeability material with wide measuring range

Primary Input Current :Iin: 0-5A

Secondary Output Current Io: 0-10mA

Nonlinearity: Precision <±0.2%;

Phase Error<±15'

Frequency : 45-1500Hz

Insulation Resistance: >500mΩ

Power Frequency Withstand Voltage: >3kV

Split-core structure, easy to install on site and easy to operate;

The magnetic core winding structure is cast with epoxy resin, and the end faces of the incision are matched, and the stability is good;

Adopt high-permeability ultra-microcrystalline core, with good linearity and high sensitivity;

Electrical fire monitoring system, fire-fighting equipment power monitoring system, rural power grid reconstruction project, intelligent power consumption system, low-current grounding system, electromagnetic relay protection, online environmental monitoring, etc.

| PERFORMANCE | ||||

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

| Voltage Level | 0.4/0.66/0.72KV | Linear Range | 5%~1000% | |

| Rated Input Current | 0~1A | Rated Frequency | 50/60Hz | |

| Rated Output | 0~0.25mA or 0~1V | Power Frequency Withstand Voltage | 3KV/min | |

| Accuracy Class | 0.5、1.0 | Insulation Strenth | 1000MΩ/500V/min | |

Mechanical Structure Parameters | Shell and Skeleton | PBT/PC Flame Retardant Grade 94-V0 | Output Method | Sheathed Lines |

Iron Core Material | Nanocrystalline | Split-core Structure | “304”Fastening with inseparable screw | |

| Sealing and Filling | Epoxy Resin | Construction Plan | Base mounting screw fixing | |

It can be used for current monitoring and protection in small current grounding systems, fire leakage systems, three-phase current unbalance detection and other equipment.

Main Feature

Enclosed by epoxy resin, good seismic performance

Perforation method, the hole diameter is from φ12mm-φ260mm, which is convenient for busbar installation

High magnetic permeability material with wide measuring range

Primary Input Current :Iin: 0-5A

Secondary Output Current Io: 0-10mA

Nonlinearity: Precision <±0.2%;

Phase Error<±15'

Frequency : 45-1500Hz

Insulation Resistance: >500mΩ

Power Frequency Withstand Voltage: >3kV

Split-core structure, easy to install on site and easy to operate;

The magnetic core winding structure is cast with epoxy resin, and the end faces of the incision are matched, and the stability is good;

Adopt high-permeability ultra-microcrystalline core, with good linearity and high sensitivity;

Electrical fire monitoring system, fire-fighting equipment power monitoring system, rural power grid reconstruction project, intelligent power consumption system, low-current grounding system, electromagnetic relay protection, online environmental monitoring, etc.

| PERFORMANCE | ||||

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

| Voltage Level | 0.4/0.66/0.72KV | Linear Range | 5%~1000% | |

| Rated Input Current | 0~1A | Rated Frequency | 50/60Hz | |

| Rated Output | 0~0.25mA or 0~1V | Power Frequency Withstand Voltage | 3KV/min | |

| Accuracy Class | 0.5、1.0 | Insulation Strenth | 1000MΩ/500V/min | |

Mechanical Structure Parameters | Shell and Skeleton | PBT/PC Flame Retardant Grade 94-V0 | Output Method | Sheathed Lines |

Iron Core Material | Nanocrystalline | Split-core Structure | “304”Fastening with inseparable screw | |

| Sealing and Filling | Epoxy Resin | Construction Plan | Base mounting screw fixing | |

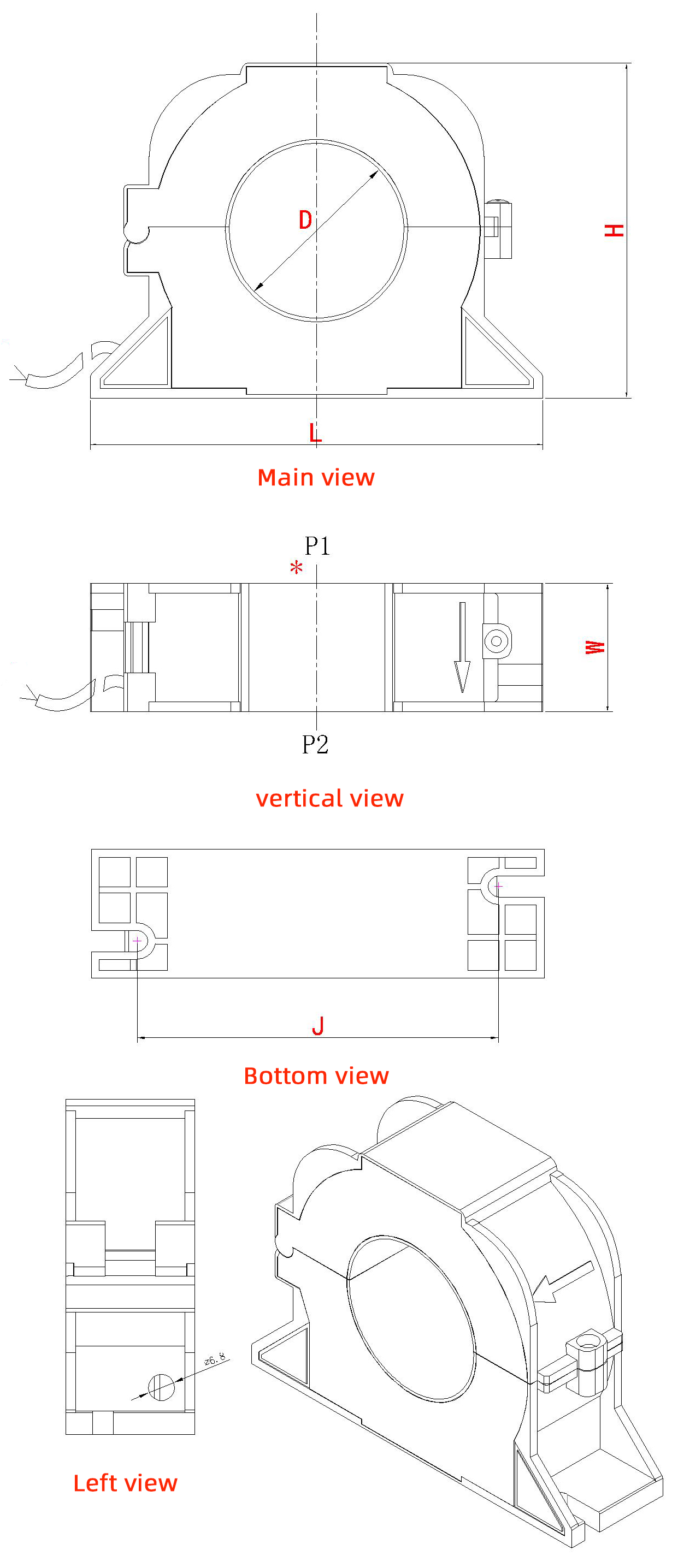

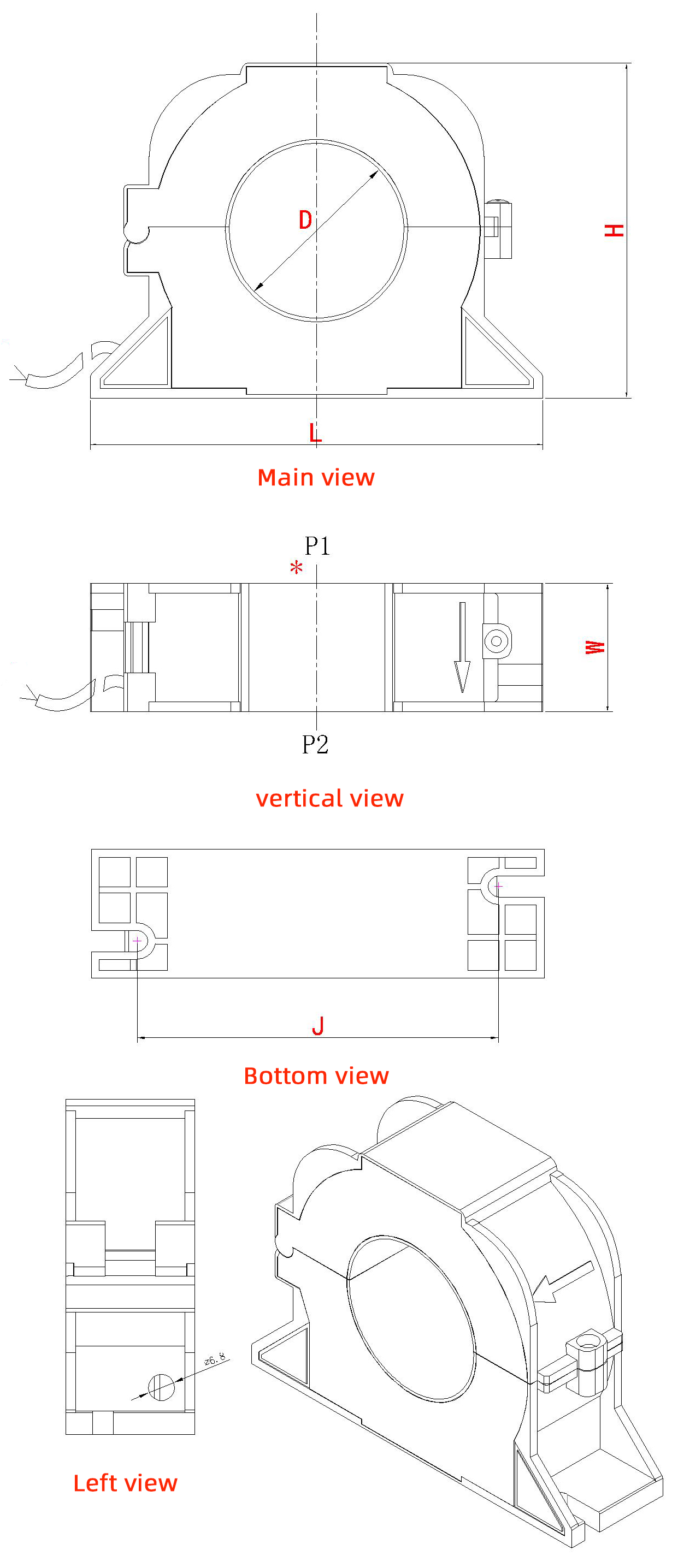

| Product Model NO. | Rated Input | Rated Output | Precision Class | Dimensions(mm) | |||||

| D | L | W | H | J | K | ||||

| TRAK-30B | 0~1A | 0~1A (0.5mA) | 0.5 1.0 | 30 | 88 | 30 | 68 | 76 | M5 |

| TRAK-45B | 45 | 116 | 33 | 86 | 92 | M5 | |||

| TRAK-65B | 65 | 130 | 33 | 105 | 110 | M6 | |||

| TRAK-80B | 80 | 160 | 33 | 128 | 143 | M6 | |||

| TRAK-100B | 100 | 188 | 33 | 154 | 178 | M6 | |||

The live wire and the neutral wire must pass through the core hole of the transformer at the same time;

Before the iron core is closed, ensure that the end face of the incision is clean, free of stains and impurities;

Use a torque wrench (electric/pneumatic) when tightening the screws, and set the torque to a reasonable range.

| Product Model NO. | Rated Input | Rated Output | Precision Class | Dimensions(mm) | |||||

| D | L | W | H | J | K | ||||

| TRAK-30B | 0~1A | 0~1A (0.5mA) | 0.5 1.0 | 30 | 88 | 30 | 68 | 76 | M5 |

| TRAK-45B | 45 | 116 | 33 | 86 | 92 | M5 | |||

| TRAK-65B | 65 | 130 | 33 | 105 | 110 | M6 | |||

| TRAK-80B | 80 | 160 | 33 | 128 | 143 | M6 | |||

| TRAK-100B | 100 | 188 | 33 | 154 | 178 | M6 | |||

The live wire and the neutral wire must pass through the core hole of the transformer at the same time;

Before the iron core is closed, ensure that the end face of the incision is clean, free of stains and impurities;

Use a torque wrench (electric/pneumatic) when tightening the screws, and set the torque to a reasonable range.