- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

TRHF

TR

It is used to monitor and analyze the internal partial discharge signal of gas-insulated combined electrical equipment (GIS) equipment. It can be analyzed centrally by the data analysis system, display and output alarms, and then monitor and evaluate the operation status of GIS equipment, so as to effectively avoid sudden accidents of GIS high-voltage equipment.

The large amount of data on partial discharge and the complex situation on site make real-time monitoring of partial discharge a challenging task. When partial discharge occurs inside the cable, the high-frequency current will propagate to the ground along the ground wire. The partial discharge detection is realized by installing a high-frequency partial discharge sensor on the ground wire to detect the high-frequency current signal. The high-frequency partial discharge sensor uses the Rogowski coil method, which surrounds multiple turns of conductive coils on the annular magnetic core material. The high-frequency alternating electromagnetic field caused by the high-frequency current passing through the center of the magnetic core will generate an induced voltage on the coil . There is no electrical connection between the measurement loop of the sensor and the measured current, which is a non-invasive detection method, and the equipment under test does not need to be shut down.

By monitoring monitoring and PD trending activity using a TRHF series high-frequency partial discharge sensor is a sensor that can be widely used in partial discharge detection of cables, switch cabinets, GIS, generators, PT cabinets, circuit breakers and other high-voltage electrical equipment of various power levels. It can be installed on the ground wire of the cable input bushing/surge capacitor, on the ground wire of the cable body or shield, on the secondary winding of the current transformer in the switchgear, on the neutral wire of the generator and transformer. Real-time online monitoring and diagnosis of the reliability of the discharge that occurs on high-voltage equipment, and realize digitalization of substation maintenance. Provide a strong foundation for end users to ensure the safe and reliable operation of the equipment during the expected life cycle of the equipment.

* Good linearity and high precision; fast response speed, which can reach ns level;

* Frequency bandwidth, can work in the range of 100kHz ~ 50MHz;

* Opened and closed structure, easy to install;

* The waterproof level can reach IP68, which can be used indoors and outdoors.

* Partial discharge online monitoring system, SF6 circuit breakers of various voltage levels, gas-

insulated combined electrical appliances (GIS) equipment, cabinet switches, column switches, transformer equipment and primary high-voltage transformers.

It is used to monitor and analyze the internal partial discharge signal of gas-insulated combined electrical equipment (GIS) equipment. It can be analyzed centrally by the data analysis system, display and output alarms, and then monitor and evaluate the operation status of GIS equipment, so as to effectively avoid sudden accidents of GIS high-voltage equipment.

The large amount of data on partial discharge and the complex situation on site make real-time monitoring of partial discharge a challenging task. When partial discharge occurs inside the cable, the high-frequency current will propagate to the ground along the ground wire. The partial discharge detection is realized by installing a high-frequency partial discharge sensor on the ground wire to detect the high-frequency current signal. The high-frequency partial discharge sensor uses the Rogowski coil method, which surrounds multiple turns of conductive coils on the annular magnetic core material. The high-frequency alternating electromagnetic field caused by the high-frequency current passing through the center of the magnetic core will generate an induced voltage on the coil . There is no electrical connection between the measurement loop of the sensor and the measured current, which is a non-invasive detection method, and the equipment under test does not need to be shut down.

By monitoring monitoring and PD trending activity using a TRHF series high-frequency partial discharge sensor is a sensor that can be widely used in partial discharge detection of cables, switch cabinets, GIS, generators, PT cabinets, circuit breakers and other high-voltage electrical equipment of various power levels. It can be installed on the ground wire of the cable input bushing/surge capacitor, on the ground wire of the cable body or shield, on the secondary winding of the current transformer in the switchgear, on the neutral wire of the generator and transformer. Real-time online monitoring and diagnosis of the reliability of the discharge that occurs on high-voltage equipment, and realize digitalization of substation maintenance. Provide a strong foundation for end users to ensure the safe and reliable operation of the equipment during the expected life cycle of the equipment.

* Good linearity and high precision; fast response speed, which can reach ns level;

* Frequency bandwidth, can work in the range of 100kHz ~ 50MHz;

* Opened and closed structure, easy to install;

* The waterproof level can reach IP68, which can be used indoors and outdoors.

* Partial discharge online monitoring system, SF6 circuit breakers of various voltage levels, gas-

insulated combined electrical appliances (GIS) equipment, cabinet switches, column switches, transformer equipment and primary high-voltage transformers.

Type | TRHF-60 | |

F | Operating Frequency Range | 0.1MHz~50MHz |

S | Sensitivity | 5pC |

Z C | Transmission Impedance | 12mV/mA |

RM | Matched Impedance | 50Ω |

Ta | Operating Temperature | -40℃~+85℃ |

Ta | Storage Temperature | -40℃~+100℃ |

O | Output Interface | BNC socket or RG5850-3/SMA copper coaxial cable |

P | Protection Class | IP68 |

Φ | Bore Diameter | Φ60mm |

W | Weight | Around 1.1kg |

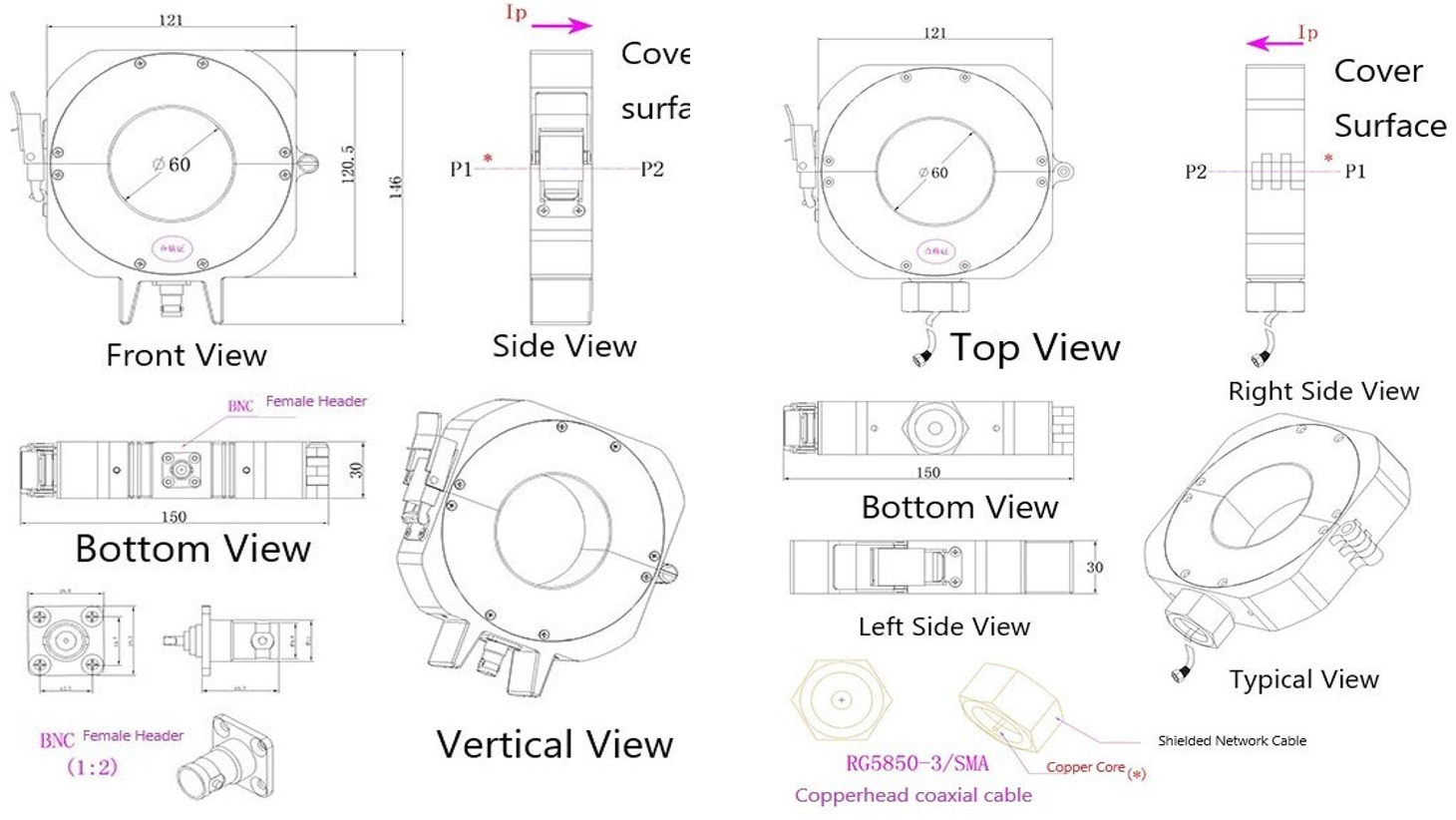

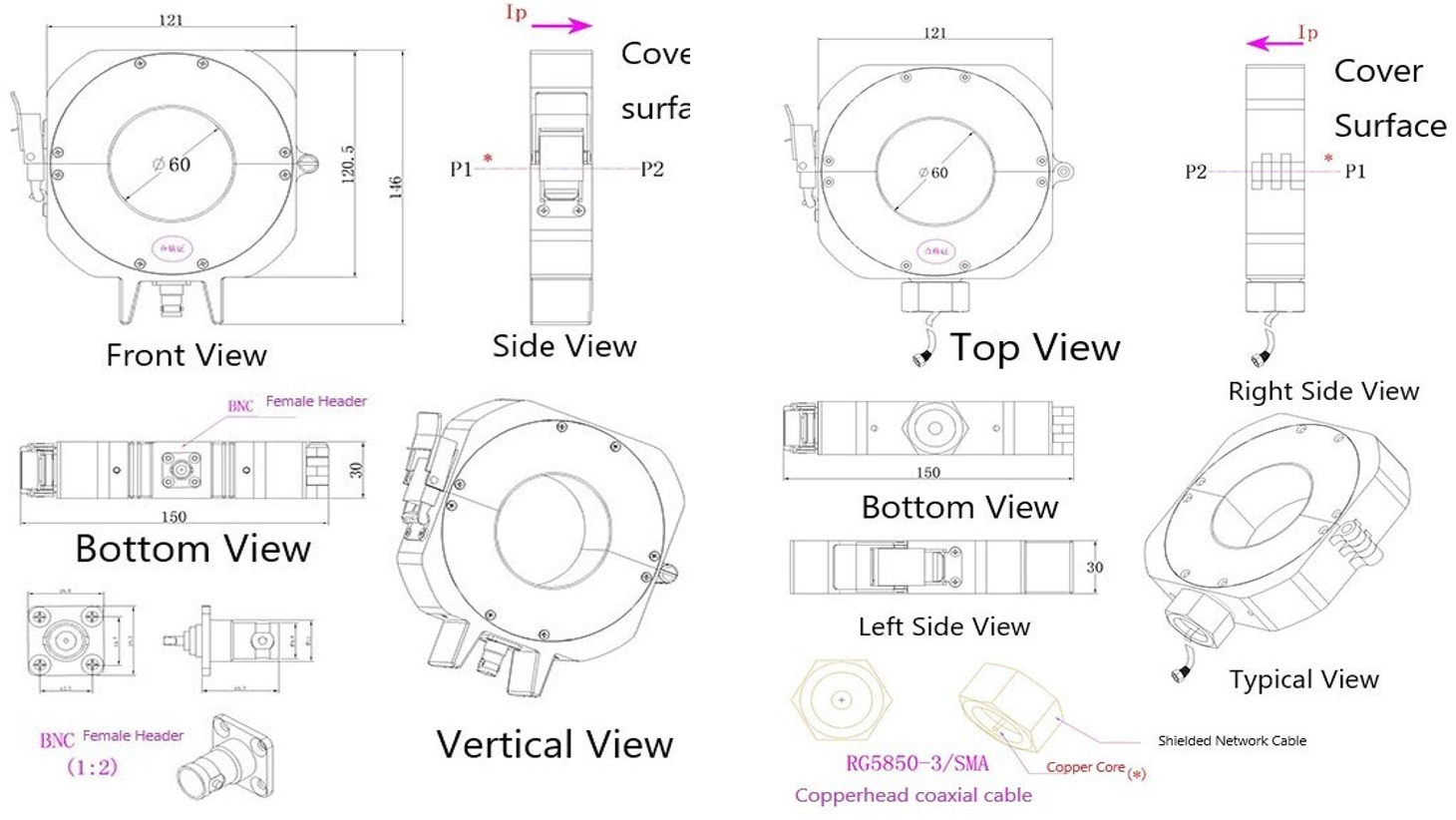

Dimension and Connection

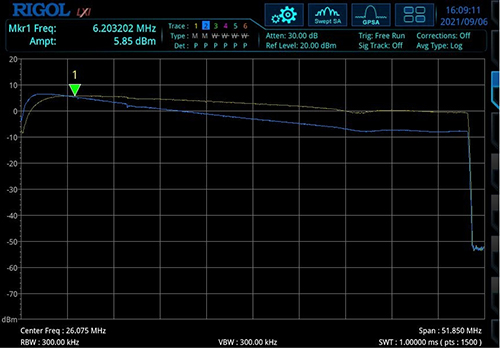

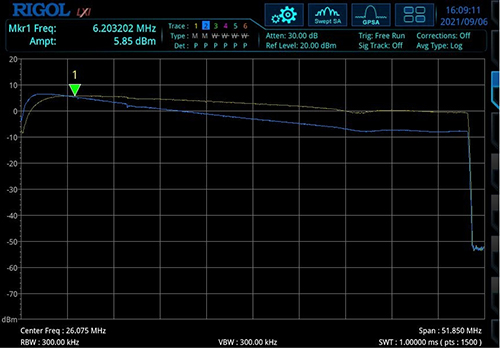

Amplitude-frequency characteristics

Type | TRHF-60 | |

F | Operating Frequency Range | 0.1MHz~50MHz |

S | Sensitivity | 5pC |

Z C | Transmission Impedance | 12mV/mA |

RM | Matched Impedance | 50Ω |

Ta | Operating Temperature | -40℃~+85℃ |

Ta | Storage Temperature | -40℃~+100℃ |

O | Output Interface | BNC socket or RG5850-3/SMA copper coaxial cable |

P | Protection Class | IP68 |

Φ | Bore Diameter | Φ60mm |

W | Weight | Around 1.1kg |

Dimension and Connection

Amplitude-frequency characteristics