- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

TRXLW

TR

It has become the first choice for sensors for online monitoring of high-voltage equipment insulation. For this kind of current sensor, it is required to have high accuracy, good anti- electromagnetic interference capability and long-term stability. The traditional passive sensor cannot guarantee the accuracy and stability of the phase transformation error, and it is difficult to meet the requirements. The micro-current sensor using active zero-flux technology has the above excellent performance, and can accurately measure the leakage current of high-voltage equipment such as transformers, current transformers, voltage transformers, coupling capacitors, and arresters.

TRXLW series passive zero-flux leakage current sensor is a micro-current sensor specially developed for on-line monitoring of high-voltage electrical equipment insulation. The material with high initial permeability is selected as the iron core, and the multi-layer metal shielding measures are adopted to adapt to the negative feedback technology circuit of the customer's PCB, which can automatically compensate the iron core and make the iron core work in an ideal zero magnetic flux state. The sensor can accurately detect the power frequency current of 100μA-700mA. The phase transformation error is not greater than 0.01°, and it has good temperature characteristics and electromagnetic field interference ability, which fully meets the accuracy of equipment sampling under complex power station field interference.

* It can accurately measure μA-level current, with high measurement accuracy and good linearity;

* Multiple shielding, strong anti-interference ability, can work in complex environment;

* Optional socket output or aviation plug output;

* Special waterproof and anti-corrosion metal shell, epoxy resin potting, can work outdoors for a long time.

*On-line monitoring of substation equipment: on-line monitoring of transformer core grounding; on-

line monitoring of high-voltage bushing insulation; on-line monitoring of metal zinc oxide arrester insulation; on-line monitoring of current, voltage transformers and capacitors; high-voltage live display.

It has become the first choice for sensors for online monitoring of high-voltage equipment insulation. For this kind of current sensor, it is required to have high accuracy, good anti- electromagnetic interference capability and long-term stability. The traditional passive sensor cannot guarantee the accuracy and stability of the phase transformation error, and it is difficult to meet the requirements. The micro-current sensor using active zero-flux technology has the above excellent performance, and can accurately measure the leakage current of high-voltage equipment such as transformers, current transformers, voltage transformers, coupling capacitors, and arresters.

TRXLW series passive zero-flux leakage current sensor is a micro-current sensor specially developed for on-line monitoring of high-voltage electrical equipment insulation. The material with high initial permeability is selected as the iron core, and the multi-layer metal shielding measures are adopted to adapt to the negative feedback technology circuit of the customer's PCB, which can automatically compensate the iron core and make the iron core work in an ideal zero magnetic flux state. The sensor can accurately detect the power frequency current of 100μA-700mA. The phase transformation error is not greater than 0.01°, and it has good temperature characteristics and electromagnetic field interference ability, which fully meets the accuracy of equipment sampling under complex power station field interference.

* It can accurately measure μA-level current, with high measurement accuracy and good linearity;

* Multiple shielding, strong anti-interference ability, can work in complex environment;

* Optional socket output or aviation plug output;

* Special waterproof and anti-corrosion metal shell, epoxy resin potting, can work outdoors for a long time.

*On-line monitoring of substation equipment: on-line monitoring of transformer core grounding; on-

line monitoring of high-voltage bushing insulation; on-line monitoring of metal zinc oxide arrester insulation; on-line monitoring of current, voltage transformers and capacitors; high-voltage live display.

Electrical Symbol | Performance parameters | Small Signal Measurement (Match client circuit) | Large Signal Measurement (Passive) | ||

Electric Performance | I N | Rated Input | 500mARMS | 10ARMS | |

IP | Measurable Range | 0.1mA-1A | 0.1-20A | ||

IOUT | Rated Output | 10mARMS | 10mARMS | ||

X | Accuracy@IPN | 0.05% | 0.20% | ||

εL | Linearity | ≤0.05% | ≤0.2% | ||

Uc | Supply Voltage | Client Circuit customization | / | ||

VOff | Offset Voltage | 1mV | / | ||

IC | Max Power Consumption | 10mA | / | ||

f | Operating Frequency | 50-400 Hz | |||

TA | Operating Temperature | -40℃… +85oC | |||

TS | Storage Temperature | -40℃…+100oC | |||

Mechanical Structure | Shell | Metal Shell | Output Mode | Socket block/shielded wire | |

Metal Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | ||

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | ||

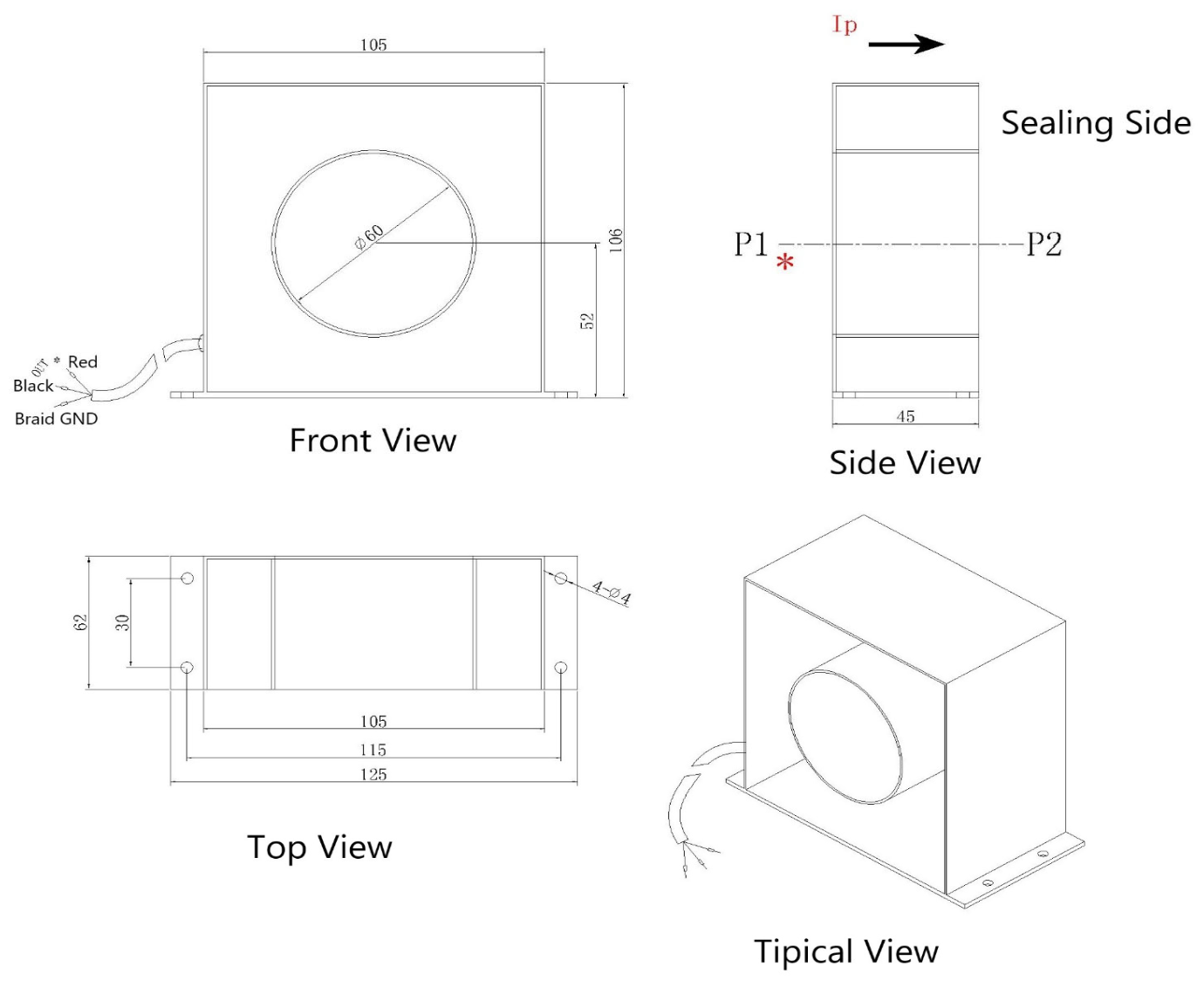

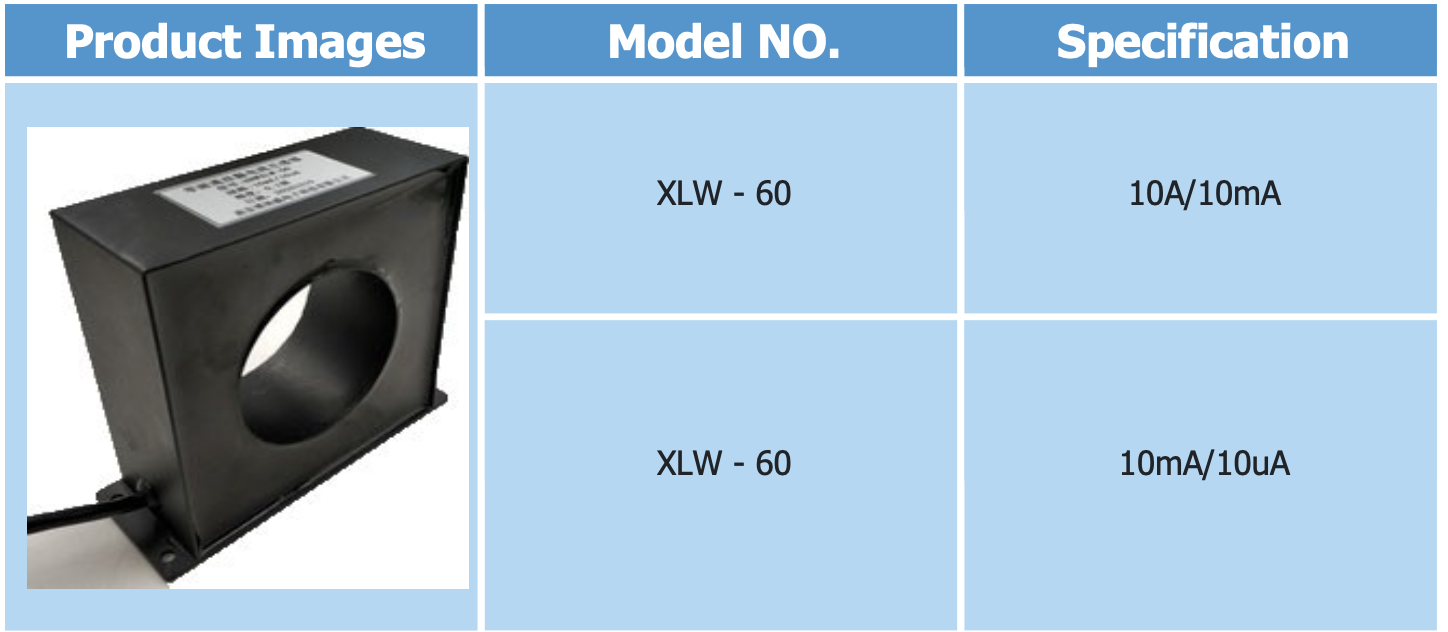

Main specification and Drawing

Note: can be customized according to customer requirements (through hole diameter, external dimensions, parameter transformation ratio)

Electrical Symbol | Performance parameters | Small Signal Measurement (Match client circuit) | Large Signal Measurement (Passive) | ||

Electric Performance | I N | Rated Input | 500mARMS | 10ARMS | |

IP | Measurable Range | 0.1mA-1A | 0.1-20A | ||

IOUT | Rated Output | 10mARMS | 10mARMS | ||

X | Accuracy@IPN | 0.05% | 0.20% | ||

εL | Linearity | ≤0.05% | ≤0.2% | ||

Uc | Supply Voltage | Client Circuit customization | / | ||

VOff | Offset Voltage | 1mV | / | ||

IC | Max Power Consumption | 10mA | / | ||

f | Operating Frequency | 50-400 Hz | |||

TA | Operating Temperature | -40℃… +85oC | |||

TS | Storage Temperature | -40℃…+100oC | |||

Mechanical Structure | Shell | Metal Shell | Output Mode | Socket block/shielded wire | |

Metal Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | ||

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | ||

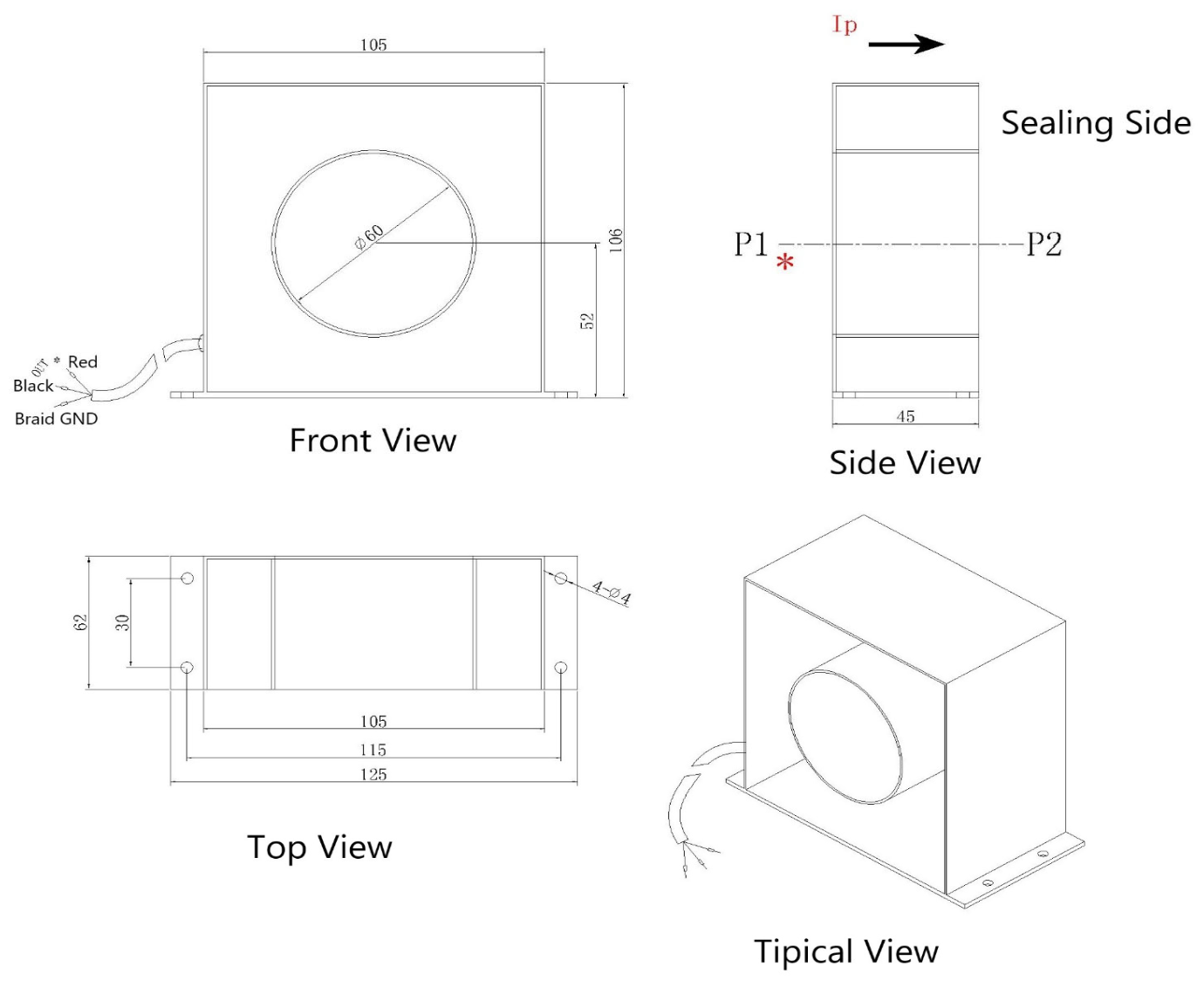

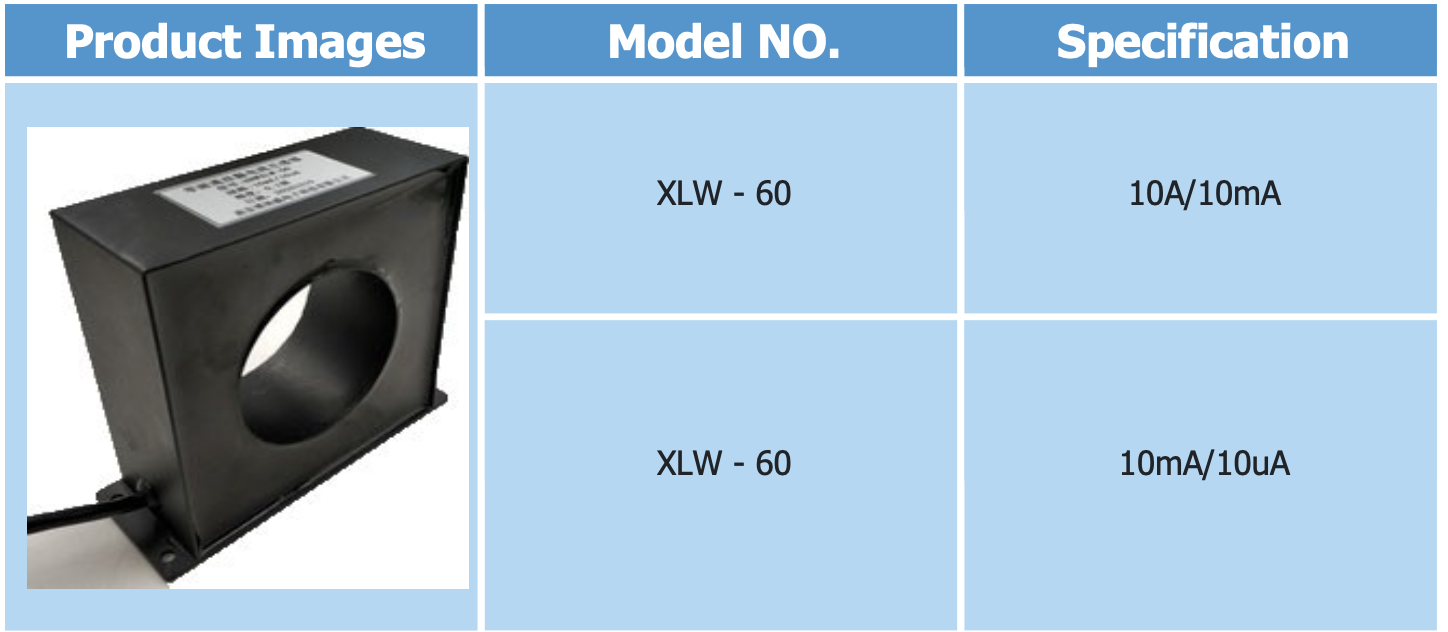

Main specification and Drawing

Note: can be customized according to customer requirements (through hole diameter, external dimensions, parameter transformation ratio)